NC part programming is the core activity of LMg Solutions Ltd.

From our involvement in a diverse range of projects for Europe’s leading Aerospace companies, we have gained unparalleled experience in providing the most effective solutions, with the ability to overcome the most complex engineering challenges.

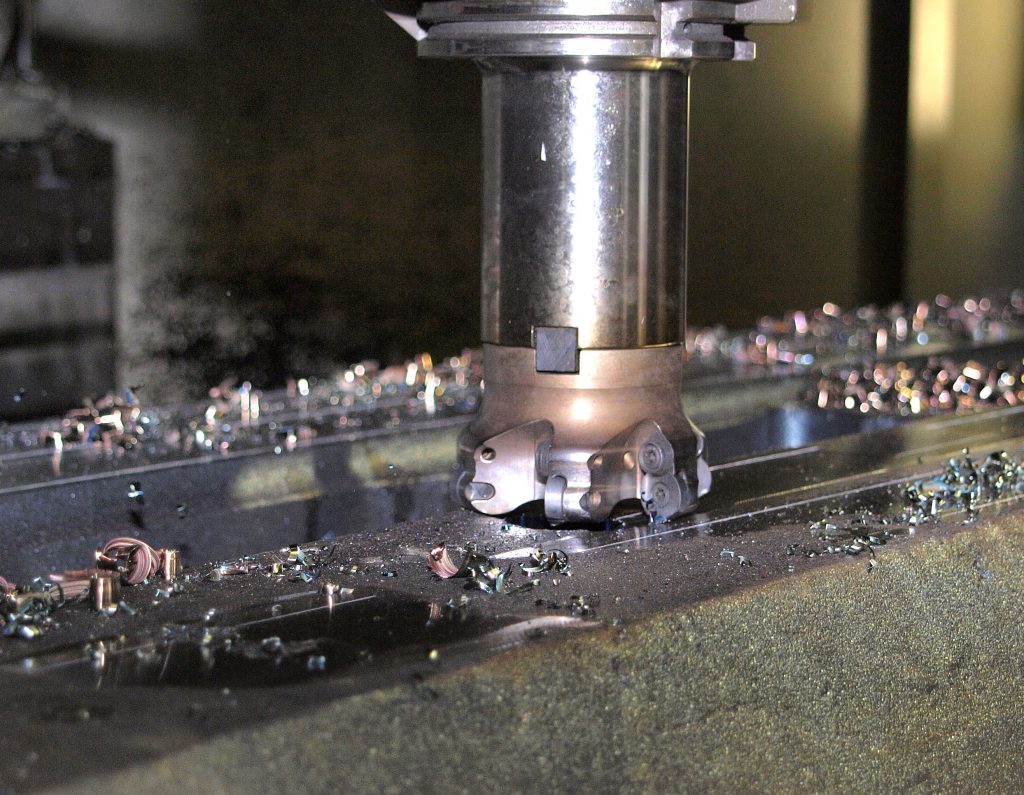

Using the latest versions of CATIA, NCL, Siemens NX and manual programming techniques, we are able to produce NC part programs for almost all CNC machines and control systems using Conventional and High speed machining of Alloy, Hard and Exotic materials.

Working from 2D drawings, or 3D solid models, from most major CADCAM systems, we combine customers established preferences for machining techniques, cutter tooling and fixturing methods with our own knowledge and experience to generate and deliver efficient NC part programs, ready for post-processing by the customer, or post-processed to load directly to the machine tool controller.

Optimisation can be achieved in many different ways and does not necessarily mean using new technology machine tools.

LMg typically consider optimisation into two catergories:-

Full optimisation:

New technology machine.

New technology cutting tools & development of cutting strategies.

Order of magnitude cycle time reduction can be achieved.

Partial optimisation:

Old technology machine.

New technology cutting tools & development of cutting strategies.

Typical cycle time savings achieved between 25% & 40%.

LMg solutions work in partnership with leading machine tool and cutting tool manufacturers developing more efficient strategies using new technology machine tools, new technology cutting tools resulting in reduced cycle times and typically improved quality. LMg`s optimisation is defining the methodology and the devlopment of the cutting strategies but also considering work holding.

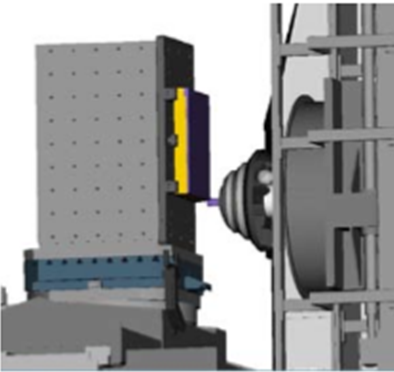

Prior to delivery, each NC part program undergoes a rigorous and detailed verification using CGTech Vericut.

False cuts, machine or cutter collisions, geometrical and dimensional errors are therefore identified and resolved before the part program is delivered and run on the customer’s machine, significantly reducing TTO time and increasing confidence that the first off part is correct.

Using the Machine Simulator and Revpost facilities within Vericut we are able to effectively convert an existing part program to run on a different machine. This is primarily of use for customers whose production schedule dictates that a particular part has to be produced on an alternative machine, or where a new machine tool is to be introduced to the production facility, or perhaps where an existing machine has been upgraded to a newer control system.

Each NC part program can be delivered in APT Source format, ready to be post-processed with the customer’s own post-processors. Alternatively, we can build a post-processor to suit the customer’s machine, enabling us to deliver NC part programs ready to load to the machine controller.

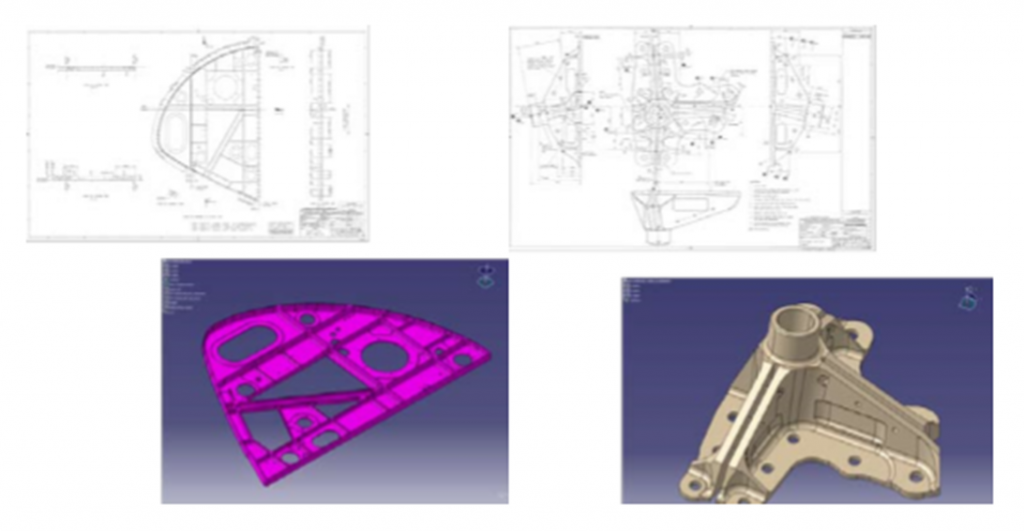

Paper to 2D/3D CAD.

Paper to CAD is a process for converting Paper drawings into 3D Models and/or 2D Drawings.

Ideal for updating existing stock drawings into 3D model format.

Manufacturing Drawings.

LMg can create full manufacturing drawings for parts to be machined including Material specifications, Dimensions, Tolerances, Surface finish Type and tolerances.

Assembly Drawings.

Assembly drawings can be created from the Top level Assembly down to each Sub assembly including Parts to be manufactured, Part numbers, fixings and bill of materials (BOM).

Verification.

All the above processes are independently verified after completion

LMg can offer a Highly skilled in-house design service which makes us unique.

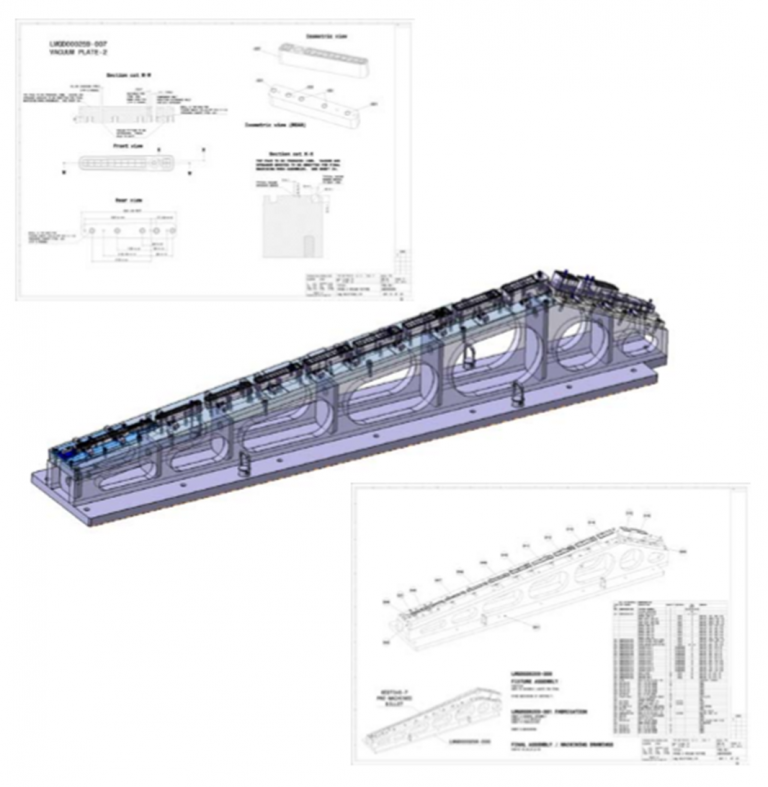

Our Team of designers using the latest 3D Design software specialise in the design of Jigs and Fixtures to develop the right solution for your bespoke requirements and budget.

From simple manual fixtures to complex vacuum fixtures.